Proper evaluation of damage to side panels is crucial for determining whether painting, patching, or replacing entire quarter panels is needed. Collision repair experts use specialized tools and access high-quality OEM or aftermarket parts to minimize downtime and restore vehicle integrity. Strategic inventory management, including demand forecasting and strong supplier relationships, ensures a steady supply of parts for efficient quarter panel replacement, enhancing customer satisfaction and road safety.

Looking to streamline your quarter panel replacement process? This guide is your compass. We delve into the intricacies of understanding quarter panel damage, emphasizing the importance of genuine parts for efficient repairs. Moreover, we explore strategies to manage availability, ensuring minimal downtime for your vehicles. By mastering these aspects, you’ll revolutionize your quarter panel replacement, contributing to faster turnarounds and enhanced customer satisfaction.

- Understanding Quarter Panel Damage and Repair

- Sourcing Genuine Parts for Efficient Replacement

- Managing Availability to Minimize Downtime

Understanding Quarter Panel Damage and Repair

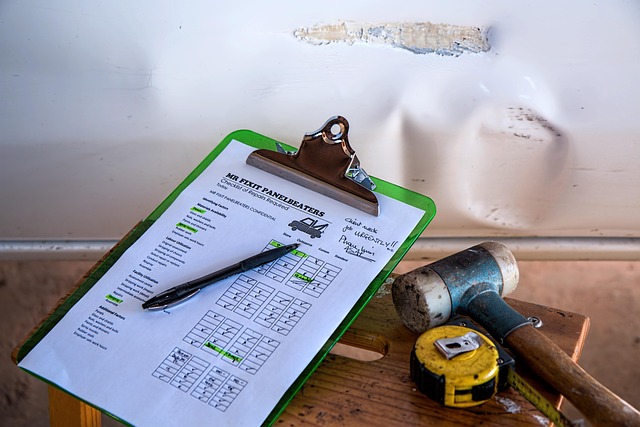

When it comes to quarter panel replacement, understanding the extent of damage is a crucial first step. The quarter panel, located at the side of a vehicle, can sustain various types of injuries in collisions or accidents, ranging from dents and dings to more severe crumpling or tearing. Proper assessment is key as it dictates the repair process. Minor damages might only require painting or patching, while extensive damage may necessitate complete quarter panel replacement, involving precise cutting and fitting of new panels to ensure a seamless fit with the car body repair.

Collision repair professionals are well-versed in handling such cases. They utilize specialized tools and techniques for accurate measurements and precise cuts during the quarter panel replacement process. Ensuring parts availability is also vital; having access to high-quality, compatible replacement parts, be it through original equipment manufacturer (OEM) or trusted aftermarket sources, guarantees a successful vehicle repair. Efficient parts management minimizes downtime and contributes to a seamless restoration of the car’s aesthetic and structural integrity in collision repair settings.

Sourcing Genuine Parts for Efficient Replacement

When undertaking a quarter panel replacement, sourcing genuine parts is paramount for efficient auto body repairs. Original Equipment Manufacturer (OEM) parts ensure not only the best fit but also optimal performance and longevity. In the case of high-end vehicles like Mercedes Benz, where precision and quality are paramount, using genuine or certified used parts from specialized dealers is crucial for a seamless collision repair process.

A well-managed parts availability ensures that auto body work can be completed promptly with minimal downtime. This involves keeping an inventory of commonly needed quarter panel replacement parts, anticipating supply chain disruptions, and fostering relationships with reliable suppliers. By prioritizing genuine components and strategic inventory management, auto body repair shops can maintain high standards in their work, ensuring customer satisfaction and safety on the road for every vehicle that passes through their shop.

Managing Availability to Minimize Downtime

Managing availability of quarter panel replacement parts is paramount to minimizing downtime for car repair services and luxury vehicle repair shops. In the event of a vehicle collision repair, having the right parts on hand ensures that repairs can be completed swiftly, reducing the time vehicles are offline. This streamlined process not only benefits customers but also boosts shop efficiency.

Effective parts availability management involves forecasting demand, maintaining strong supplier relationships, and adopting innovative inventory strategies such as just-in-time delivery. By anticipating part needs based on historical data and trends, repair shops can avoid stockouts and ensure a steady supply of replacement components for various makes and models. This proactive approach ultimately contributes to safer roads and happier customers.

Effective quarter panel replacement is crucial for restoring vehicle aesthetics and functionality. By understanding common damage types and implementing strategic parts sourcing, such as procuring genuine components from reliable suppliers, automotive workshops can streamline the repair process. Additionally, managing availability of replacement parts ensures minimal downtime, enhancing customer satisfaction in the face of competitive market demands. These practices contribute to efficient quarter panel repair, maintaining vehicle value and safety standards.