Quarter panel replacement is a critical process for auto body shops, focusing on restoring vehicle integrity and safety after collisions. Skilled technicians expertly remove and replace damaged side panels, utilizing advanced tools like CAD design and robotic welding for precise fits. Strict quality control measures, including inspections and high-quality materials, ensure original manufacturing standards are met. Best practices involve rigorous training, industry updates, and customer feedback to deliver exceptional, long-lasting results in quarter panel replacement services.

In the realm of auto body repair, quarter panel replacement is a critical procedure ensuring vehicle structural integrity and aesthetic appeal. This comprehensive guide delves into the intricate process, highlighting its significance in achieving top-notch repairs. We explore quality control measures that auto body shops employ to maintain high standards, guaranteeing customer satisfaction. Furthermore, we offer best practices for auto body professionals to excel in quarter panel replacement, fostering a culture of excellence within their workshops.

- Understanding Quarter Panel Replacement: The Process and Importance

- Quality Control Measures for Ensuring Top-Notch Repairs

- Best Practices for Auto Body Shops to Maintain High Standards

Understanding Quarter Panel Replacement: The Process and Importance

Quarter panel replacement is a critical process within auto body shops, playing a significant role in both vehicle restoration and safety. This procedure involves the meticulous removal and installation of a car’s quarter panel, which is the rear or front side panel that connects to the doors and roof. It’s often damaged during collisions, requiring skilled technicians to carefully cut out the affected area and seamlessly install a new, precision-cut panel.

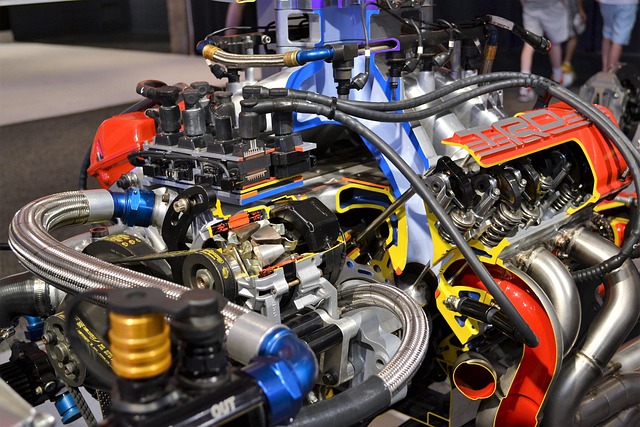

The importance of this replacement extends beyond mere aesthetics. A correctly fitted quarter panel ensures structural integrity, preventing further damage and enhancing the vehicle’s overall safety. Auto dent repair specialists leverage advanced techniques, including computer-aided design (CAD) and robotic welding, to guarantee accurate measurements and a seamless fit during collision repair center operations. This meticulous attention to detail is vital, as it determines not just the car’s curb appeal but also its ability to withstand future accidents, making quarter panel replacement an indispensable aspect of quality control in auto body shops.

Quality Control Measures for Ensuring Top-Notch Repairs

In the realm of quarter panel replacement, quality control is paramount to ensuring that each repair mirrors the precision and integrity of the original manufacturing standards. Auto body shops employing top-tier collision repair services must institute rigorous protocols to guarantee customer satisfaction and vehicle safety. This involves meticulous inspection processes where every detail—from panel fitment to paint finish—is scrutinized under a magnifying glass. Skilled technicians utilize specialized tools and their expertise to detect even the subtlest imperfections, ensuring that replacement parts seamlessly integrate with the existing vehicle structure.

Beyond simple repairs, auto detailing plays a crucial role in enhancing the overall aesthetics of vehicles post-quarter panel replacement. Proficient collision repair services go above and beyond by employing advanced techniques and materials to restore and protect the vehicle’s exterior. This meticulous approach not only ensures that the repaired area matches the surrounding panels in texture and color but also adds a layer of protection against future damage, thereby extending the life of the vehicle and its appearance.

Best Practices for Auto Body Shops to Maintain High Standards

Maintaining high standards in quarter panel replacement is paramount for auto body shops to ensure customer satisfaction and long-lasting results. Best practices include implementing rigorous quality control measures throughout the repair process. This involves thorough inspection of both new and damaged panels, ensuring proper fitment and alignment before final installation. Auto body shops should also invest in high-quality materials and tools to guarantee durability and longevity of the replacement parts.

Additionally, fostering a culture of continuous training and improvement among technicians is essential. Staying updated with industry trends, new technologies, and techniques for car damage repair and auto detailing will help maintain optimal standards. Regular reviews of work quality and customer feedback can provide valuable insights for refining processes, ultimately enhancing the overall vehicle bodywork experience.

In conclusion, mastering quarter panel replacement is paramount for auto body shops aiming to deliver top-notch repairs. By implementing robust quality control measures and adhering to best practices, shops can ensure customer satisfaction and maintain their reputation in a competitive market. Understanding the process and prioritizing quality are key steps towards achieving excellence in vehicle restoration.